In today’s construction industry, there is a constant quest for faster, more economical, and energy-efficient solutions. One material playing a significant role in this development is “sandwich panels.” Sandwich panels are an innovative material solution widely used in various construction projects.

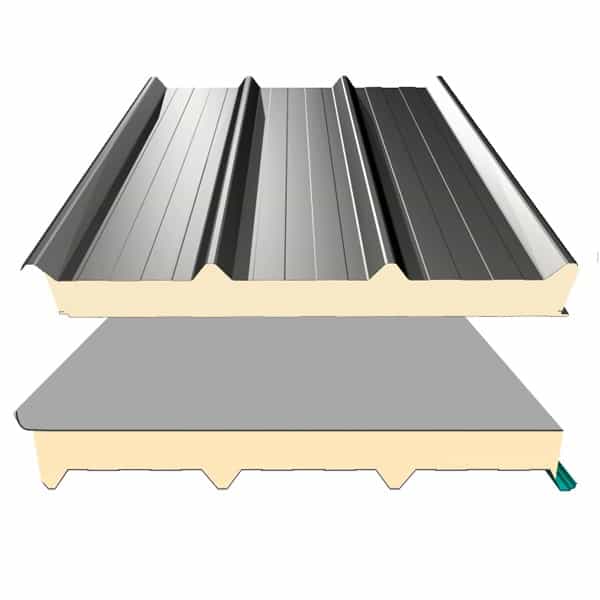

Structure and Materials: Sandwich panels typically consist of a core material sandwiched between two different outer layers. The core material is often insulation materials such as polyurethane, polystyrene, or mineral wool. The core material enhances the panel’s insulation properties, contributing to energy savings. The outer layers are usually made of durable materials like steel, aluminum, or fiber cement, enhancing the panels’ robustness.

Applications: Sandwich panels find applications in walls, roofs, cold storage facilities, industrial plants, and even structural systems. These panels expedite construction processes due to their easy assembly and lightweight structure. Furthermore, their high insulation properties reduce energy costs, making them an environmentally friendly option.

Advantages: Sandwich panels offer several advantages. Their lightweight nature facilitates transportation and installation. Additionally, their high insulation properties enhance the energy efficiency of buildings, providing sustainable construction solutions. Features like fire resistance, water impermeability, and suitability for various climate conditions make sandwich panels adaptable to diverse environments.

Conclusion: Sandwich panels provide an ideal solution for professionals in the construction sector seeking aesthetics, durability, and energy efficiency. This innovative material significantly contributes to the construction industry by making building projects more sustainable and economical.

In today’s construction industry, there is a constant quest for faster, more economical, and energy-efficient solutions. One material playing a significant role in this development is “sandwich panels.” Sandwich panels are an innovative material solution widely used in various construction projects.

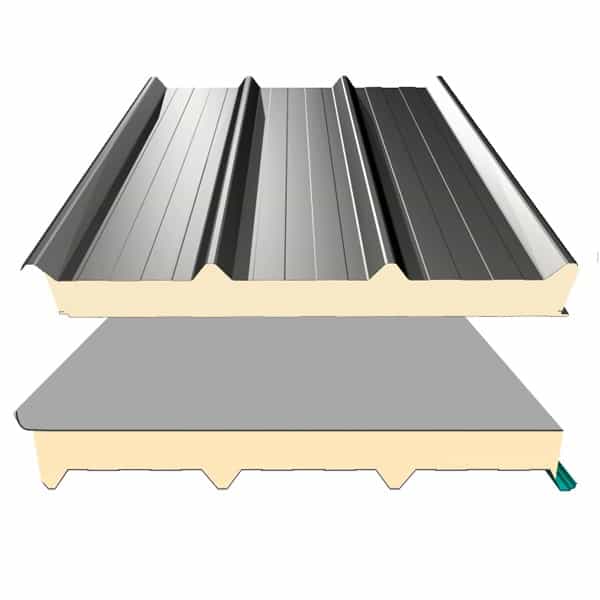

Structure and Materials: Sandwich panels typically consist of a core material sandwiched between two different outer layers. The core material is often insulation materials such as polyurethane, polystyrene, or mineral wool. The core material enhances the panel’s insulation properties, contributing to energy savings. The outer layers are usually made of durable materials like steel, aluminum, or fiber cement, enhancing the panels’ robustness.

Applications: Sandwich panels find applications in walls, roofs, cold storage facilities, industrial plants, and even structural systems. These panels expedite construction processes due to their easy assembly and lightweight structure. Furthermore, their high insulation properties reduce energy costs, making them an environmentally friendly option.

Advantages: Sandwich panels offer several advantages. Their lightweight nature facilitates transportation and installation. Additionally, their high insulation properties enhance the energy efficiency of buildings, providing sustainable construction solutions. Features like fire resistance, water impermeability, and suitability for various climate conditions make sandwich panels adaptable to diverse environments.

Conclusion: Sandwich panels provide an ideal solution for professionals in the construction sector seeking aesthetics, durability, and energy efficiency. This innovative material significantly contributes to the construction industry by making building projects more sustainable and economical.